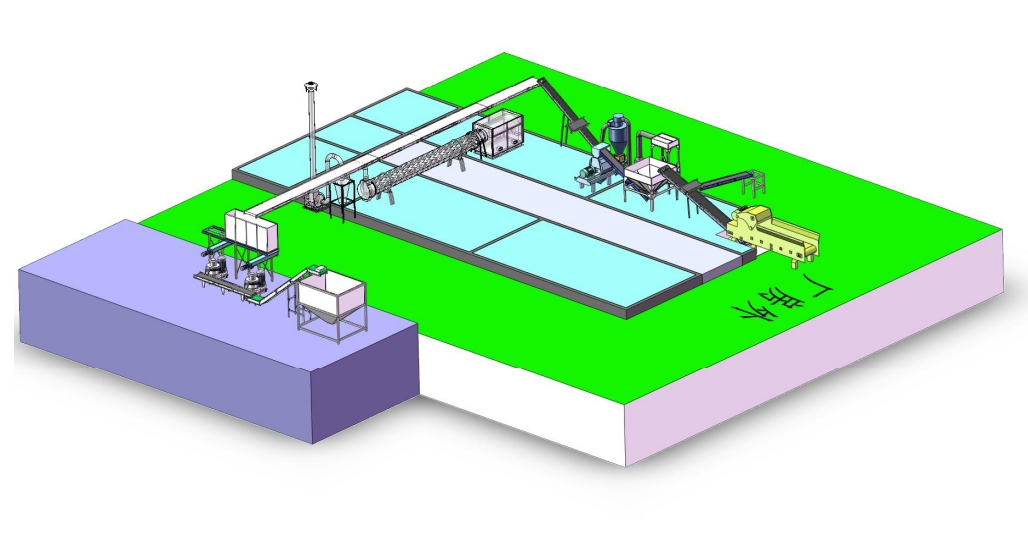

Wood pellet production line

Release time:

2025-04-21

The process of wood pellet production line mainly includes the following steps:

Chipping and crushing: Firstly, wood and logs needs to be preliminary chipped into uniform chips(30*30*5mm) and then further crushed into sawdust the crusher. The purpose of this step is to reduce large pieces of wood, branches, and other raw materials to a size suitable for subsequent processing.

Drying: If the moisture content of wood chips is high, they need to be dried in a dryer. Drying can reduce the moisture content of wood chips, making them more suitable for subsequent granulation process.

Pellet making: The dried wood particles enter the pellet machine and are compressed into pellets by the pellet machine. This step is a crucial step in forming the final product.

Cooling: The compressed particles need to be cooled by a cooling machine to ensure their stability and quality.

Packiing and transportation: The finished pellets are bagged by a packing machine and transported to places such as power plants and boiler plants that require fuel.

Equipment composition: The equipment of the wood pellet production line mainly includes wood crusher, wood pulverizer, wood pellet dryer, wood pellet machine, etc. These devices work together to complete the entire process from raw material processing to finished product production

Latest News

2025-12-02