High efficiency hammer mill

Category:

Hammer Crusher

Chat with us now for a quick response.

Get expert sales advice within 12 hours.

Keyword:

High efficiency hammer mill

Product introduction

An efficient crusher is a device that allows materials to enter the crushing chamber, where they are crushed by the impact force, shear force, and mutual impact force generated by a high-speed rotating rotor. After screening through a sieve, the materials reach the specified specifications of the product.

Features as follows:

1. The motor is directly connected to the rotor, with a speed of 3000r/min, low power loss, and high efficiency

2. Double side screen discharge, increase discharge area, and improve production capacity.

3. Unique structural design of the body, smooth cutting and no dead corners

4. The mesh aperture can be adjusted to ensure the required particle size of the finished product. The combination of cyclone dust removal and bag dust removal has better dust removal effect.

Product parameters

| Model | Power(kw) | Output(t/h) | Hammer qty. |

| JS65*55 | 55 | 1.0-1.5 | 48 |

| JS65*75 | 75 | 1.5-2.0 | 72 |

| JS65*90 | 90 | 2.5-3.0 | 96 |

| JS65*100 | 110 | 3.0-3.5 | 110 |

| JS65*130 | 132 | 3.5-4.0 | 132 |

| JS65*130 | 132/160 | 4.0-5.0-6.0 | 132 |

| JS1600*1000 | 185/200 | 6.5-7.5-8.0 | 240 |

PRODUCT APPLICATION

Straw

Straw pellet

Sawduat

Sawduat pellet

Peanut shell

Nutshell pellet

Straw

Straw pellet

Grass

Grass pellet

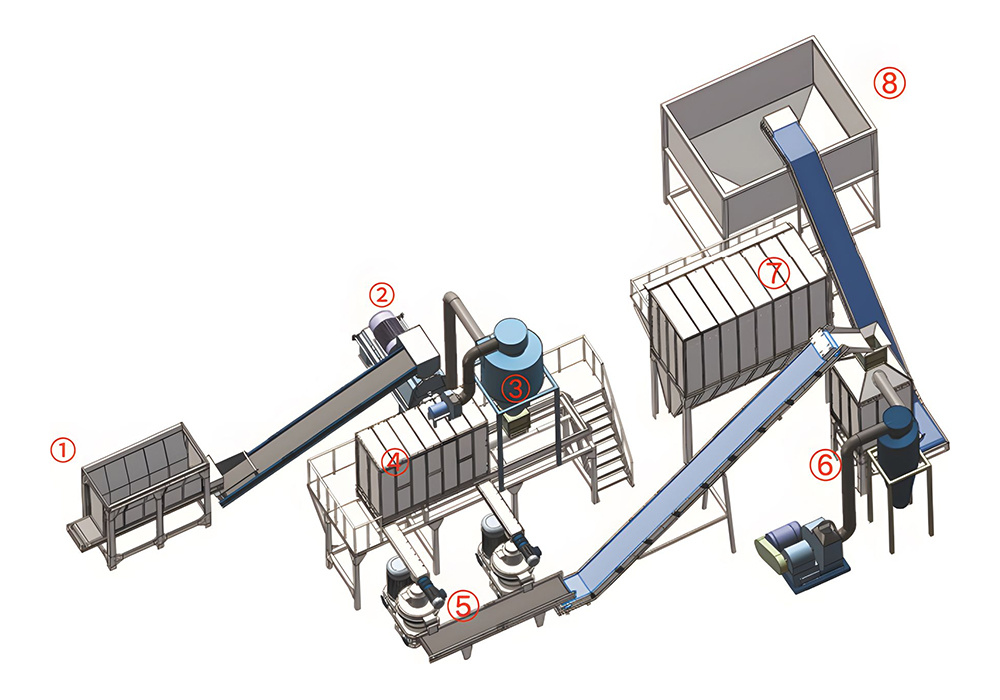

Complete production line flow chart

① Double twisted roller silo

② Crusher

③ Shakron discharge

④ Hydraulic silo

⑤ Particle machine

⑥ Cooling machine

⑦ Pulse dust removal

⑧ Finished product silo

Factory description

Shipping Packaging

Customer communication

CUSTOMER VISIT

CUSTOMER CASE

FAQ

RELATED PRODUCTS

SERVICE SUPPORT

Guide customers to select suitable device models

According to the special requirements of customers, design and manufacture products to solve related technical problems for customers

A full set of equipment warranty for one year (except for damaged parts)

GET A FREE QUOTE