JS560 wood pellet machine

Category:

Pellet Machine

Chat with us now for a quick response.

Get expert sales advice within 12 hours.

Keyword:

JS560 wood pellet machine

Product introduction

JS560 vertical centrifugal ring die pellet machine is currently the newest generation and most efficiency type in China. It adopts a large modulus hard tooth surface helical gear reducer, strengthened main shaft, and has the advantages of strong power output, stable equipment use, low failure rate, and low production cost. It is absolutely the main machine model in the biomass fuel pellet industry.

Features as follows:

1. Strong automation level, stable operation, no need for dedicated personnel to take care of.

2. Increased discharge area and increased production capacity

3. The design of the pressure roller without locking nut structure results in low fuel consumption and extended bearing life.

4. Heavy duty gearbox transmission with 5-10 times increased gear strength, low failure rate, and strong stability.

5.Circulating gear oil lubrication reduces fuel consumption costs and protects bearings.

Product parameters

| Model | Power (kw) | Pellet Diameter (mm) | Output (T/h) | Dimension (mm) | Weight (T) |

| JS560 | 90/110/132 | 6-12 | 1.5-2.0 | 2200*1300*1600 | 5.8 |

JS560 Wood Pellet Machine: An Ideal Solution for Pellet Production

The JS560 wood pellet machine is a remarkable piece of equipment designed for efficient and high - quality wood pellet production.

1. Design and Construction

This pellet machine is engineered with precision. It features a robust and durable structure. The key components are made from high - quality materials that can withstand continuous operation under high pressure. The machine is designed to have a stable base, which minimizes vibrations during the pellet - making process. This not only ensures the safety of the operation but also helps in maintaining the accuracy of pellet formation.

2. Production Capacity

The JS560 has an impressive production capacity. It is capable of producing a significant amount of wood pellets per hour. This makes it suitable for both small - scale and medium - scale pellet production facilities. Whether it is for domestic heating needs or small - to - medium - sized industrial applications, this machine can meet the demand. For example, in a small - scale workshop, it can produce enough pellets to supply a local community’s heating requirements during the winter months.

3. Pellet Quality

The pellets produced by the JS560 are of excellent quality. The machine compresses the wood materials evenly, resulting in pellets with a uniform shape and density. The high - quality pellets have a smooth surface and are less likely to break during transportation or storage. These pellets have a high calorific value, which means they can release a large amount of heat when burned, making them an efficient fuel source.

4. Energy Efficiency

The JS560 is designed with energy - saving in mind. It utilizes an advanced power transmission system that reduces energy loss during operation. Compared to some traditional pellet machines, it requires less power input to produce the same amount of pellets. This not only helps in reducing the production cost but also makes it more environmentally friendly by consuming less electricity.

5. Ease of Operation and Maintenance

Operating the JS560 is relatively straightforward. It comes with a user - friendly control panel that allows operators to easily adjust the settings such as the speed of the pellet - making process. In terms of maintenance, the machine is designed for easy access to its internal components. Regular maintenance tasks such as cleaning and part replacement can be carried out with ease, which helps in prolonging the service life of the machine.

In conclusion, the JS560 wood pellet machine is a great choice for those who are looking for a reliable, efficient, and high - quality wood pellet production solution.

A pellet machine is a device used to make the required pellets from wet powder or block dry materials. Its main function is to press raw materials into particles through a sieve, suitable for processing various types of feed, biomass fuels, etc. The main features of the pellet machine include easy installation and disassembly of the screen mesh, convenient disassembly, and easy cleaning.

Pellet machine is widely used for feed processing, such as straw feed pellet machine, wheat bran feed pellet machine, soybean meal feed pellet machine, etc. It can process raw materials such as corn, soybean meal, straw, grass, rice husk, etc. In addition, pellet machines are also used in the field of biomass fuels, with uniform granulation, high efficiency, high combustion value, and no pollution, making them a good fuel alternative to coal.

The classification of pellet machines includes ring die pellet machines and flat die pellet machines. The former produces more uniform and efficient pellets, while the latter is suitable for different raw materials and production needs. With the increasing awareness of environmental protection, the market prospects of pellet machines are becoming increasingly broad, becoming a new type of energy-saving and environmentally friendly product.

PRODUCT APPLICATION

Straw

Straw pellet

Sawduat

Sawduat pellet

Peanut shell

Nutshell pellet

Straw

Straw pellet

Grass

Grass pellet

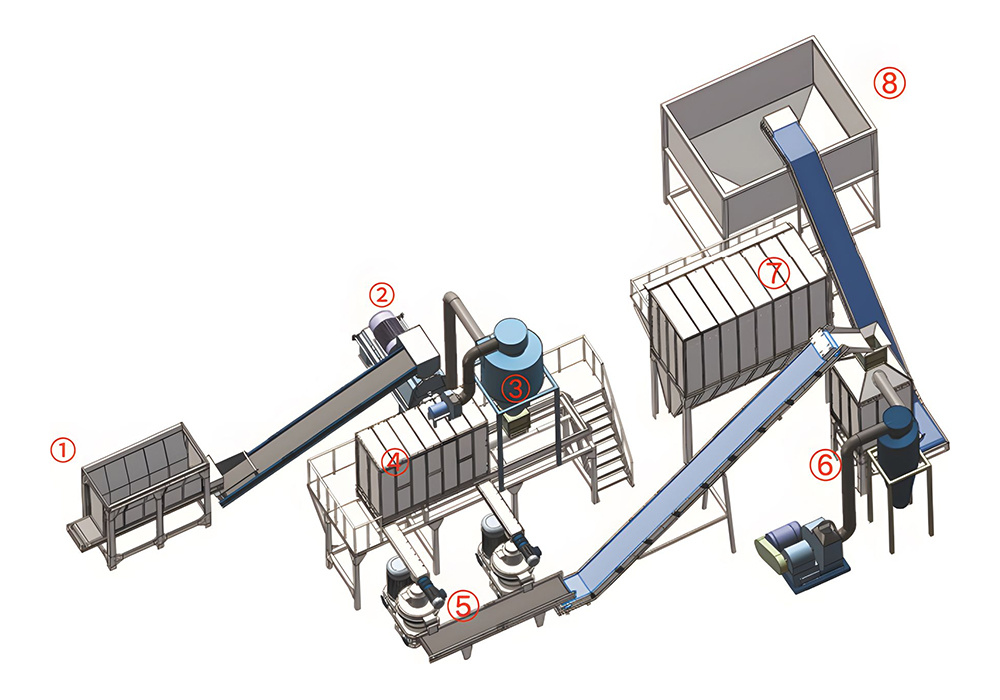

Complete production line flow chart

① Double twisted roller silo

② Crusher

③ Shakron discharge

④ Hydraulic silo

⑤ Particle machine

⑥ Cooling machine

⑦ Pulse dust removal

⑧ Finished product silo

Factory description

Shipping Packaging

Customer communication

CUSTOMER VISIT

CUSTOMER CASE

FAQ

RELATED PRODUCTS

SERVICE SUPPORT

Guide customers to select suitable device models

According to the special requirements of customers, design and manufacture products to solve related technical problems for customers

A full set of equipment warranty for one year (except for damaged parts)

GET A FREE QUOTE