Pellet coller

Category:

Pellet Cooler And Packing

Chat with us now for a quick response.

Get expert sales advice within 12 hours.

Keyword:

Pellet coller

Product introduction

Counter current cooler is a relatively advanced new type of cooler internationally, which uses the principle of counter current cooling to cool high-temperature and high humidity granular materials. Natural wind passes vertically through the material layer, first coming into contact with the material layer, and gradually heating up the hot air that comes into contact with the hot material. The direction of the airflow is opposite to the direction of the material flow, gradually cooling the particles in the forward direction. The temperature of the cooled particles is room temperature ± 10-15 ℃.

Features as follows:

1.Avoid surface cracking caused by rapid cooling of particles due to direct contact between cold air and high-temperature particles.

2.Air enters the cooler from all directions at its bottom, with a large air intake area, high utilization rate, low energy consumption, easy operation, and significant cooling effect.

3. The particle cooling is sufficient and uniform, using a unique slide valve vibration mechanical discharge, which runs smoothly and discharges smoothly.

Product parameters

| Model | Output (t/h) | Cooling volume(m³) | Cooling time(min) | Pellet temperature after cooling(℃) | Total power(kw) | Air volume (m³/h) |

| JS1.2 | 0.8-1.2 | 1.2 | ≥10min | Room temperature±10-15℃ | 0.18+4 | 5000 |

| JS1.5 | 12.-2 | 1.5 | ≥10min | 0.25+5.5 | 9000 | |

| JS.5 | 2.0-4.0 | 2.5 | ≥10min | 0.25+15 | 13500 | |

| JS4 | 4.0-6.0 | 4.0 | ≥10min | 0.37+22 | 18000 | |

| JS6 | 5.0-8.0 | 6.0 | ≥10min | 0.37+37 | 27000 |

PRODUCT APPLICATION

Straw

Straw pellet

Sawduat

Sawduat pellet

Peanut shell

Nutshell pellet

Straw

Straw pellet

Grass

Grass pellet

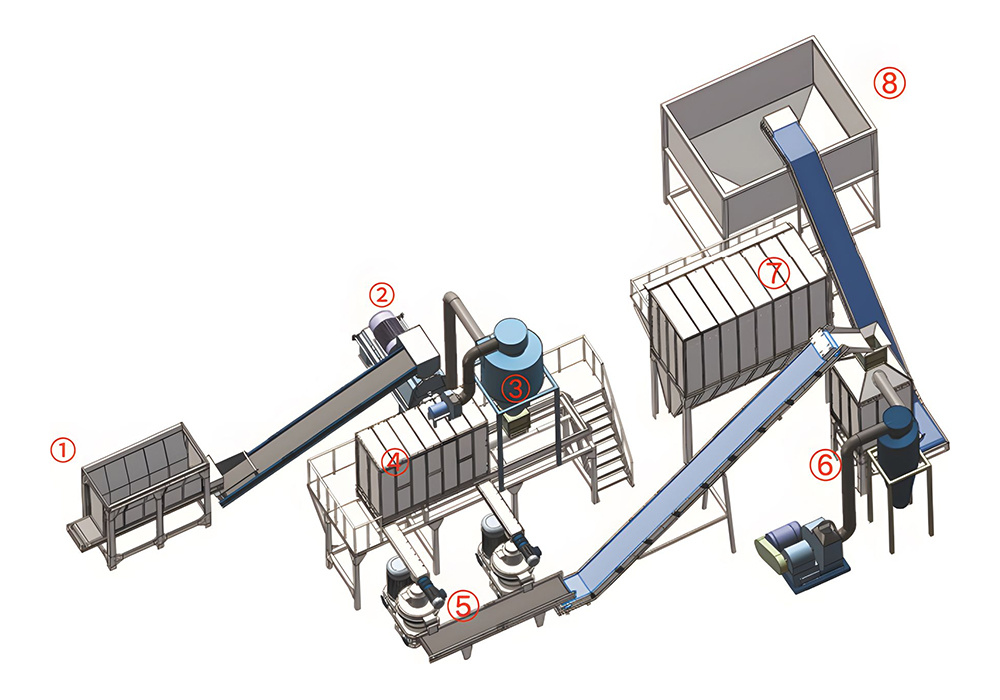

Complete production line flow chart

① Double twisted roller silo

② Crusher

③ Shakron discharge

④ Hydraulic silo

⑤ Particle machine

⑥ Cooling machine

⑦ Pulse dust removal

⑧ Finished product silo

Factory description

Shipping Packaging

Customer communication

CUSTOMER VISIT

CUSTOMER CASE

FAQ

RELATED PRODUCTS

SERVICE SUPPORT

Guide customers to select suitable device models

According to the special requirements of customers, design and manufacture products to solve related technical problems for customers

A full set of equipment warranty for one year (except for damaged parts)

GET A FREE QUOTE