Rice husk pellet machine

Category:

Pellet Machine

Chat with us now for a quick response.

Get expert sales advice within 12 hours.

Keyword:

Rice husk pellet machine

Product introduction

Rice husk pellet machine is a specialized equipment to process biomass materials such as rice husks into pellet fuel. The rice husk pellet machine crushes, compresses, and shapes rice husks into high-density pellets through specific processes. These pellets have characteristics such as high calorific value, environmental friendliness, and renewability, and are widely used in industries such as boilers, kilns, industrial kilns, and biomass power plants.

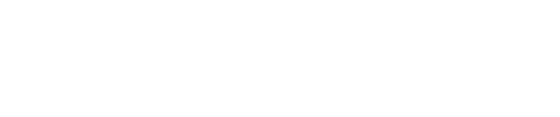

The main performance and characteristics of the rice husk pellet machine include:

Efficient motor and energy-saving design: The latest designed pure copper high-efficiency motor for pellet machines is used, which significantly saves energy consumption. Under the same power, energy consumption can be reduced by about 10%.

Specialized gearbox and powerful horsepower: equipped with a specialized gearbox suitable for the particle manufacturing industry, with parallel hard tooth surface design, strong impact resistance, and even stronger horsepower.

Flexible lubrication system: providing dual options of butter free and pure thin oil lubrication, with circulating oil flow and good cooling effect, which is conducive to the long-term operation of the equipment.

In addition, the rice husk pellet machine also has the following advantages:

Environmentally friendly and clean energy: Rice husk particles generate a large amount of heat after combustion, have a long combustion time, are sulfur free, have very little ash content, and produce very low nitrogen oxides, which belongs to environmentally friendly and clean energy 1.

Wide applicability: The rice husk pellet machine is not only suitable for processing rice husks, but also for processing other biomass materials such as sawdust and straw, providing more possibilities for the utilization of biomass energy.

The emergence of rice husk pellet machines not only solves the problem of processing biomass materials such as rice husks, but also provides an efficient way for their reuse, which helps to promote the development and application of biomass energy.

A pellet machine is a device used to make the required pellets from wet powder or block dry materials. Its main function is to press raw materials into particles through a sieve, suitable for processing various types of feed, biomass fuels, etc. The main features of the pellet machine include easy installation and disassembly of the screen mesh, convenient disassembly, and easy cleaning.

Pellet machine is widely used for feed processing, such as straw feed pellet machine, wheat bran feed pellet machine, soybean meal feed pellet machine, etc. It can process raw materials such as corn, soybean meal, straw, grass, rice husk, etc. In addition, pellet machines are also used in the field of biomass fuels, with uniform granulation, high efficiency, high combustion value, and no pollution, making them a good fuel alternative to coal.

The classification of pellet machines includes ring die pellet machines and flat die pellet machines. The former produces more uniform and efficient pellets, while the latter is suitable for different raw materials and production needs. With the increasing awareness of environmental protection, the market prospects of pellet machines are becoming increasingly broad, becoming a new type of energy-saving and environmentally friendly product.

PRODUCT APPLICATION

Straw

Straw pellet

Sawduat

Sawduat pellet

Peanut shell

Nutshell pellet

Straw

Straw pellet

Grass

Grass pellet

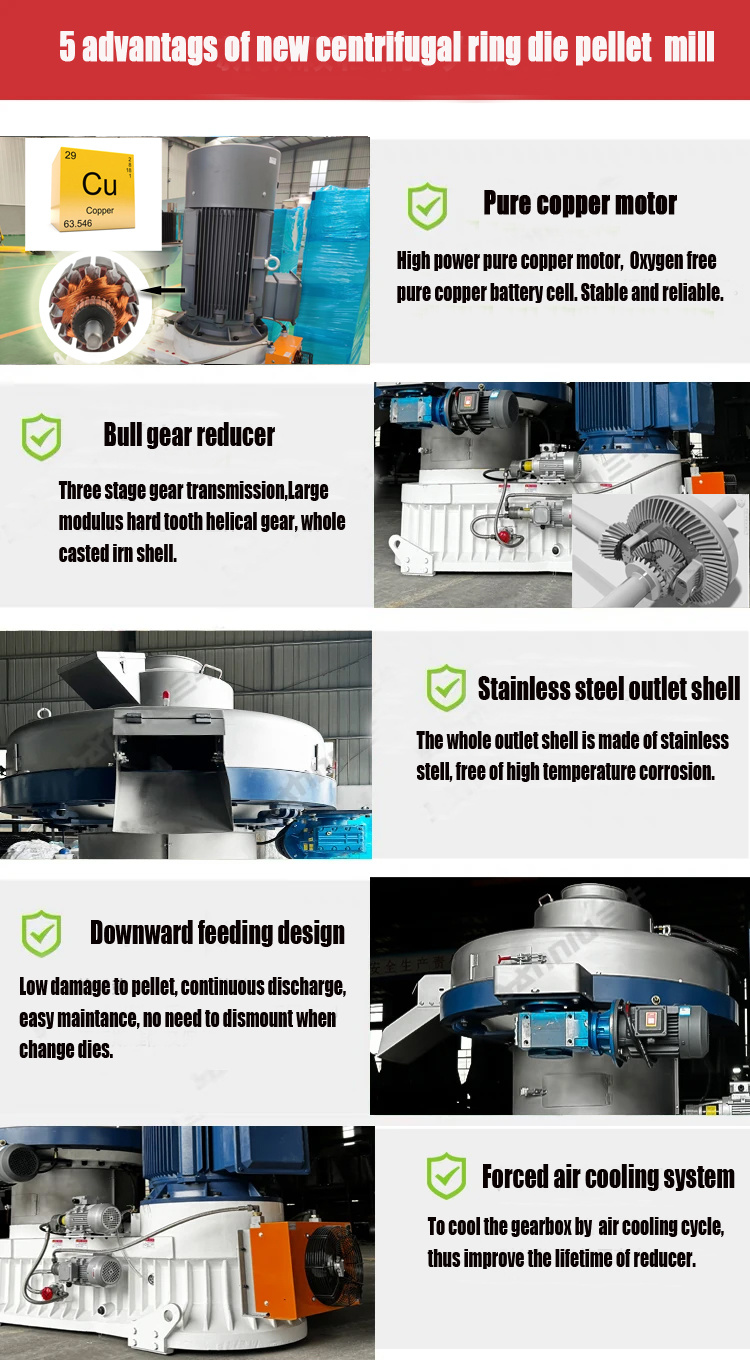

Complete production line flow chart

① Double twisted roller silo

② Crusher

③ Shakron discharge

④ Hydraulic silo

⑤ Particle machine

⑥ Cooling machine

⑦ Pulse dust removal

⑧ Finished product silo

Factory description

Shipping Packaging

Customer communication

CUSTOMER VISIT

CUSTOMER CASE

FAQ

RELATED PRODUCTS

SERVICE SUPPORT

Guide customers to select suitable device models

According to the special requirements of customers, design and manufacture products to solve related technical problems for customers

A full set of equipment warranty for one year (except for damaged parts)

GET A FREE QUOTE