Rice straw pellet producton line

Category:

Pellet Line

Chat with us now for a quick response.

Get expert sales advice within 12 hours.

Keyword:

Rice straw pellet producton line

Product introduction

The production process of rice straw pellets mainly includes the following steps:

1. Crushing:

Use a rotary cutter or professional grinder to crush straw into small particles. The degree of crushing should be moderate, neither too coarse to facilitate subsequent processes, nor too fine to avoid affecting the firmness of pellet formation.

2. Drying (if required):

If the moisture content of straw is high, it needs to be dried. The crushed materials will be dried by a rotary dryer to achieve a suitable moisture content of 10-15%.

3. Mixing (optional):

As needed, other additives such as starch, vegetable oil, etc. can be added during the mixing process to improve the viscosity and heat of the particles. This step is not necessary, it depends on the requirements of the final product.

4. Pellet making:

Send the crushed (and possibly mixed) material into the pellet machine, which extrudes materials through high temperature and high pressure to form shaped straw pellets. This step is a key link in the production process, and the control of temperature and pressure is crucial for the quality and stability of the final product.

Cooling:

After granulation, high-temperature straw pellets need to enter the cooling machine through a conveyor belt for cooling. The purpose of cooling is to prevent particles from cracking or deforming due to overheating, ensuring the stability of particles in appearance and structure.

Packaging:

The cooled particles will enter the packaging machine for packaging. According to the requirements, choose suitable packaging materials for transportation and storage.

In summary, the production process of rice straw granules includes steps such as raw material preparation and processing, crushing, drying (if necessary), mixing (optional), granulation, cooling, and packaging. Each step requires careful design and control to ensure the quality and performance of the final product.

The biomass pellet production line is a comprehensive production system that processes biomass raw materials into pellet fuels. It usually includes the following main steps: raw material collection and crushing, drying, granulation, cooling, and packaging.

Biomass pellet production lines can be classified by the type of raw materials.

Wood based biomass pellet production line: The main raw materials include sawdust, wood chips, wood powder, waste wood, etc., suitable for wood waste generated by wood processing plants, furniture factories, etc.

Straw based biomass pellet production line: The main raw materials are agricultural waste such as corn straw, wheat straw, and rice straw, which are suitable for agricultural planting areas.

Other biomass pellet production lines: using peanut shells, edible mushroom residue, urban greening waste, etc., have great development potential.

A modern pellet production line adopts advanced integrated technologies, and has a high degree of automation, high production efficiency, and stable product quality.

A complete biomass pellet production line usually includes the following sections and corresponding equipment:

Chipping section: Crushing large raw materials into small pieces.

Crushing section: further pulverize the crushed raw materials into fine powder.

Drying section: Dry the fine powder to the appropriate moisture content.

Granulation section: Press the dried fine powder into pellet fuel.

Cooling section: Cool the produced pellet fuel to room temperature.

Packaging section: Packaging the cooled pellet fuel.

Biomass pellet production lines are widely used in the processing of various biomass raw materials, such as waste from wood processing plants, agricultural waste, etc. Its advantages include:

Energy conservation and emission reduction: converting waste biomass resources into clean energy to reduce environmental pollution.

Reduce costs: Utilize waste as raw materials to lower production costs.

Improve energy utilization efficiency: The biomass pellet fuel produced has high calorific value, good combustion performance, and is suitable for use in various combustion equipment.

PRODUCT APPLICATION

Straw

Straw pellet

Sawduat

Sawduat pellet

Peanut shell

Nutshell pellet

Straw

Straw pellet

Grass

Grass pellet

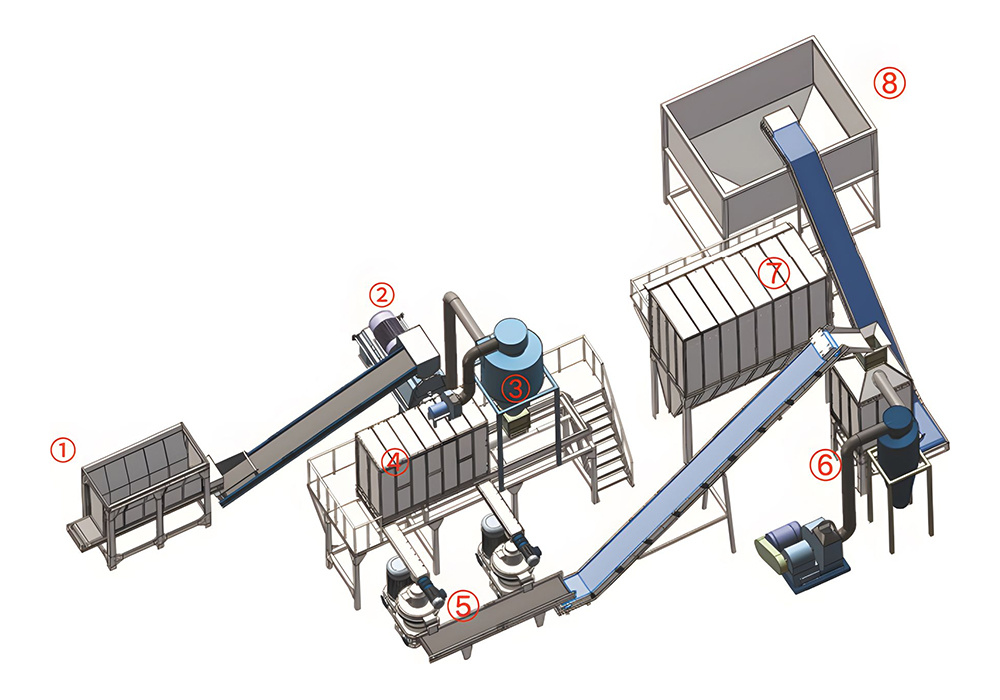

Complete production line flow chart

① Double twisted roller silo

② Crusher

③ Shakron discharge

④ Hydraulic silo

⑤ Particle machine

⑥ Cooling machine

⑦ Pulse dust removal

⑧ Finished product silo

Factory description

Shipping Packaging

Customer communication

CUSTOMER VISIT

CUSTOMER CASE

FAQ

RELATED PRODUCTS

SERVICE SUPPORT

Guide customers to select suitable device models

According to the special requirements of customers, design and manufacture products to solve related technical problems for customers

A full set of equipment warranty for one year (except for damaged parts)

GET A FREE QUOTE