Rotary dryer

Category:

Dryer

Chat with us now for a quick response.

Get expert sales advice within 12 hours.

Keyword:

Rotary dryer

Product introduction

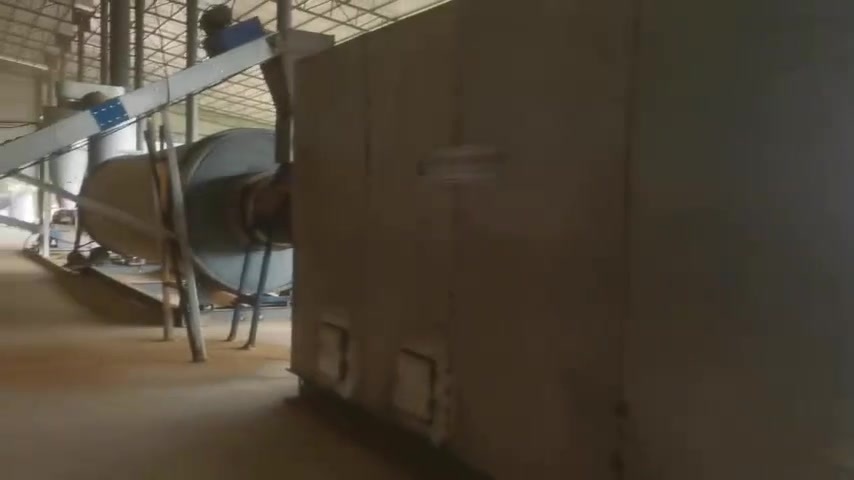

The drum dryer is mainly composed of a cylinder body, roller rings, base stop rollers, and tail dust removal equipment. A drying equipment that achieves a drying effect by allowing hot air and materials to come into contact inside the same body, and through the design of the lifting plate structure inside the barrel, allowing the materials and hot air to fully contact each other.

Features as follows:

1. The lifting plate inside the cylinder is designed with multiple angles to form a material curtain inside the cylinder.

2. The material has a high contact surface with hot air, high thermal efficiency utilization, and good drying effect.

3. Reasonable structural design, conducive to maintenance.

4. The material has a wide range of applications and can be used for drying powders, wood chips, filamentous materials, etc.

Product parameters

| Model | Power(kw) | Evaporation(t/h) | Gradient | thickness |

| JS1.2*12*1 | 5.5+7.5+3 | 0.27-0.54 | 3-5° | 10-12mm |

| JS1.5*12*1 | 7.5+18.5+4 | 0.42-0.85 | 3-5° | 10-12mm |

| JS1.5*18*1 | 5.5+18.5+4 | 0.42-0.85 | 3-5° | 10-12mm |

| JS1.8*18*1 | 11+22+4 | 1 | 3-5° | 10-12mm |

| JS2.0*24*1 | 11+37+7.5 | 1.0-3.0 | 3-5° | 14-18mm |

| JS2.2*12*1 | 11+22+4 | 1.2 | 3-5° | 14-18mm |

| JS1.2*24*1 | 15+27+5.5 | 1.82-3.658 | 3-5° | 14-18mm |

| JS2.5*18*1 | 4*4+55+5.5 | 2.7-4.1 | 3-5° | 14-18mm |

| JS2.8*18*1 | 5.5*4+90+5.5 | 3.5-5.5 | 3-5° | 16-20mm |

Below two customer cases of JSØ1.8*18 rotary dryer.

PRODUCT APPLICATION

Straw

Straw pellet

Sawduat

Sawduat pellet

Peanut shell

Nutshell pellet

Straw

Straw pellet

Grass

Grass pellet

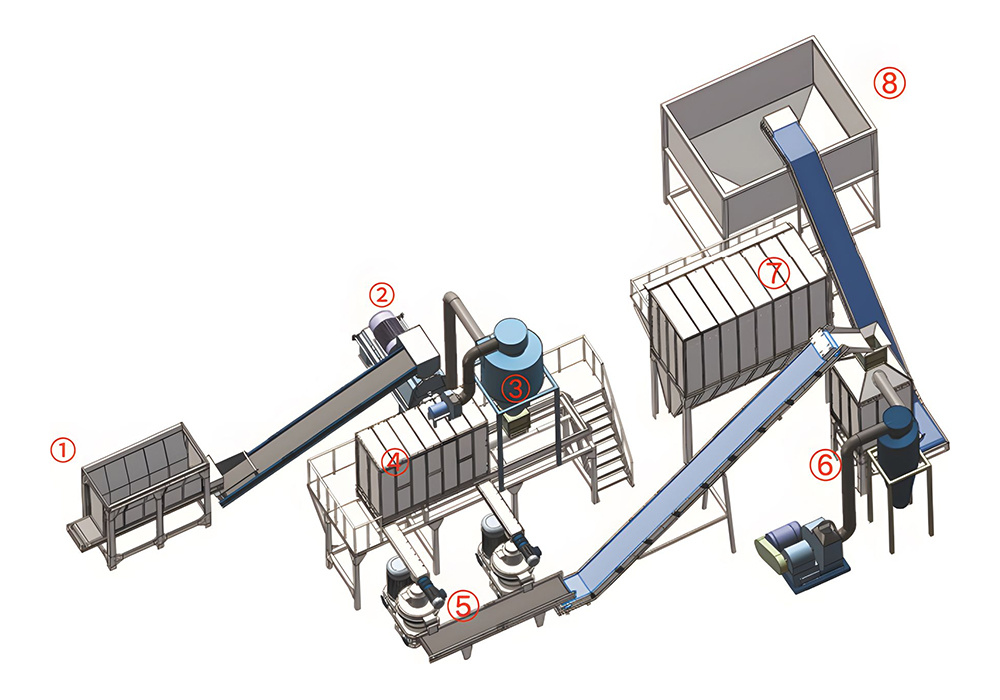

Complete production line flow chart

① Double twisted roller silo

② Crusher

③ Shakron discharge

④ Hydraulic silo

⑤ Particle machine

⑥ Cooling machine

⑦ Pulse dust removal

⑧ Finished product silo

Factory description

Shipping Packaging

Customer communication

CUSTOMER VISIT

CUSTOMER CASE

FAQ

RELATED PRODUCTS

SERVICE SUPPORT

Guide customers to select suitable device models

According to the special requirements of customers, design and manufacture products to solve related technical problems for customers

A full set of equipment warranty for one year (except for damaged parts)

GET A FREE QUOTE