Rotary screener

Category:

Auxiliary Accessories

Chat with us now for a quick response.

Get expert sales advice within 12 hours.

Keyword:

Rotary screener

Product introduction

The drum screen is mainly composed of a motor, a reducer, a drum device, a frame, a sealing cover, and an inlet and outlet. The drum device is installed obliquely on the frame. The motor is connected to the drum device through a coupling via a reducer, driving the drum device to rotate around its axis. After the material enters the drum device, due to the inclination and rotation of the drum, the material on the screen surface reverses and rolls, causing qualified materials to be discharged through the bottom discharge port of the drum, and unqualified materials to be discharged through the discharge port at the tail of the drum. Due to the flipping and rolling of materials inside the drum, materials stuck in the sieve holes can be ejected to prevent blockage of the sieve holes.

Product Parameter

| Model | Output(t/h) | Dimension(mm) | Power(kw) |

| JS100*2 | 1-2 | 2800*1300*1460 | 1.5 |

| JS130*3 | 1.5-4 | 4420*1500*3800 | 3 |

| JS150*4 | 3-5 | 5160*1700*4400 | 4 |

| JS180*5 | 5-10 | 6300*2200*2600 | 4 |

| JS200*6 | 8-12 | 7000*2500*5000 | 5.5 |

PRODUCT APPLICATION

Straw

Straw pellet

Sawduat

Sawduat pellet

Peanut shell

Nutshell pellet

Straw

Straw pellet

Grass

Grass pellet

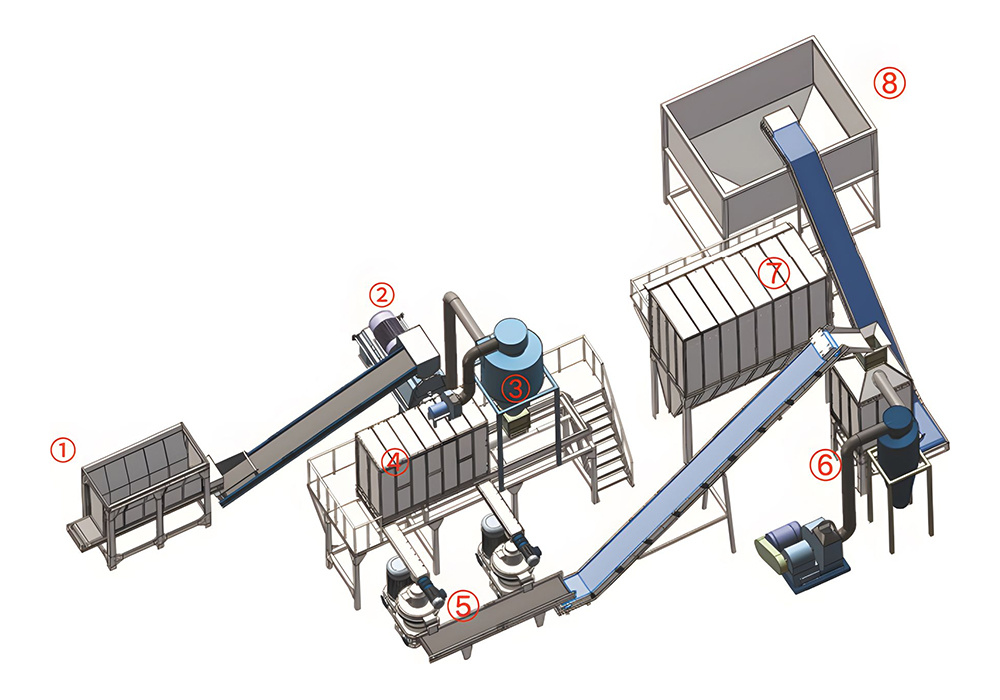

Complete production line flow chart

① Double twisted roller silo

② Crusher

③ Shakron discharge

④ Hydraulic silo

⑤ Particle machine

⑥ Cooling machine

⑦ Pulse dust removal

⑧ Finished product silo

Factory description

Shipping Packaging

Customer communication

CUSTOMER VISIT

CUSTOMER CASE

FAQ

RELATED PRODUCTS

SERVICE SUPPORT

Guide customers to select suitable device models

According to the special requirements of customers, design and manufacture products to solve related technical problems for customers

A full set of equipment warranty for one year (except for damaged parts)

GET A FREE QUOTE