waste solid pellet machine

Category:

Pellet Machine

Chat with us now for a quick response.

Get expert sales advice within 12 hours.

Keyword:

waste solid pellet machine

Product introduction

Solid waste pellet machine is a specialized equipment to process solid waste. Its main function is to convert various solid waste into pellet substances for subsequent processing and utilization. This equipment has significant advantages in the field of solid waste treatment, and can achieve efficient and environmentally friendly waste treatment.

The following is a detailed introduction to the solid waste pellet machine:

There are various types of solid waste pellet machines, such as inclined mixing pellet machines, fly ash mixing pellet machines, etc., all of which have the function of converting solid waste into pellets.

They convert waste into particles with a certain shape and particle size through specific processes and mechanisms such as mixing, granulation, stirring, etc. These particles have good physical and chemical properties, making them easy to store, transport, and reuse.

Working principle:

The working principle of a solid waste pellet machine usually includes steps 2 such as raw material pretreatment, mixing and granulation, drying and cooling, screening and packaging.

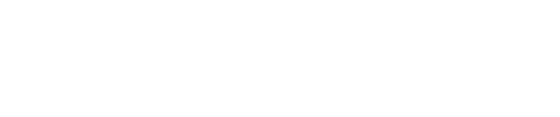

Main advantages:

Efficient mixing and granulation: The solid waste pellet machine can process a large amount of solid waste materials in a short period of time and produce particles that meet the requirements. Its high mixing efficiency and uniformity contribute to improving the overall efficiency of solid waste treatment.

Solid waste resource utilization: This equipment can convert solid waste materials into valuable granular products, such as converting household waste into fertilizer particles and industrial waste into particles that can be used for fuel or other purposes, achieving the resource utilization of waste and reducing environmental pollution.

Environmental protection and cleanliness: The equipment pays attention to environmental protection and clean production during operation, reducing pollution and damage to the environment.

Usage scenario:

Solid waste pellet machines are widely used in the fields of industrial and household waste treatment, especially playing an important role in garbage classification and recycling in large and medium-sized cities and residential areas.

Meanwhile, in farms and other places where solid waste needs to be processed, pellet machines have also demonstrated their unique advantages and application value.

In summary, the solid waste pellet machine, as an efficient and environmentally friendly waste treatment equipment, has broad application prospects and enormous potential in the field of solid waste treatment.

A pellet machine is a device used to make the required pellets from wet powder or block dry materials. Its main function is to press raw materials into particles through a sieve, suitable for processing various types of feed, biomass fuels, etc. The main features of the pellet machine include easy installation and disassembly of the screen mesh, convenient disassembly, and easy cleaning.

Pellet machine is widely used for feed processing, such as straw feed pellet machine, wheat bran feed pellet machine, soybean meal feed pellet machine, etc. It can process raw materials such as corn, soybean meal, straw, grass, rice husk, etc. In addition, pellet machines are also used in the field of biomass fuels, with uniform granulation, high efficiency, high combustion value, and no pollution, making them a good fuel alternative to coal.

The classification of pellet machines includes ring die pellet machines and flat die pellet machines. The former produces more uniform and efficient pellets, while the latter is suitable for different raw materials and production needs. With the increasing awareness of environmental protection, the market prospects of pellet machines are becoming increasingly broad, becoming a new type of energy-saving and environmentally friendly product.

PRODUCT APPLICATION

Straw

Straw pellet

Sawduat

Sawduat pellet

Peanut shell

Nutshell pellet

Straw

Straw pellet

Grass

Grass pellet

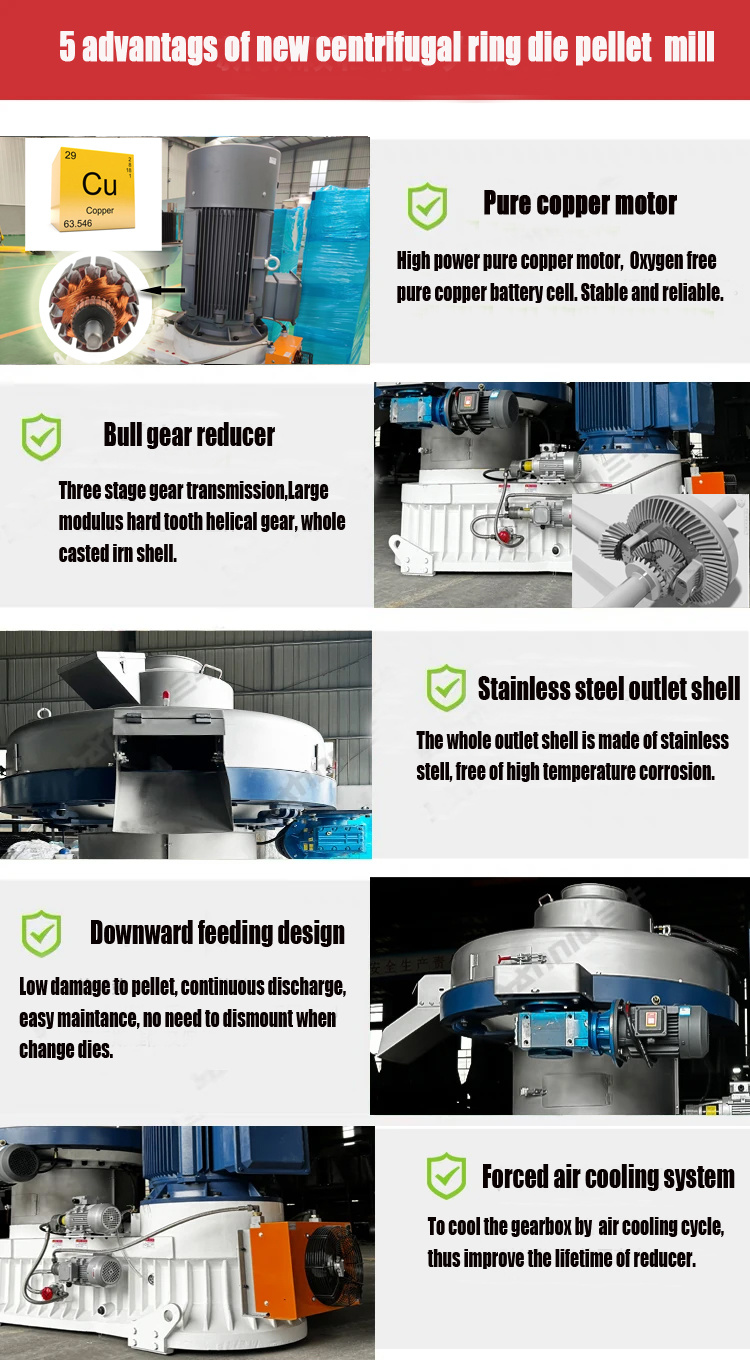

Complete production line flow chart

① Double twisted roller silo

② Crusher

③ Shakron discharge

④ Hydraulic silo

⑤ Particle machine

⑥ Cooling machine

⑦ Pulse dust removal

⑧ Finished product silo

Factory description

Shipping Packaging

Customer communication

CUSTOMER VISIT

CUSTOMER CASE

FAQ

RELATED PRODUCTS

SERVICE SUPPORT

Guide customers to select suitable device models

According to the special requirements of customers, design and manufacture products to solve related technical problems for customers

A full set of equipment warranty for one year (except for damaged parts)

GET A FREE QUOTE